Ion Implanter Disk Refurbishment & Coatings

Extend the lifetime, lower the cost-of-ownership, and improve the performance of ion implant tools with Coherent disk refurbishment and coating services.

Coherent has extensive capabilities for the repair, refurbishment, and remanufacture of any ion implanter disk or heat sink. This includes all makes and models of batch-processing ion implanters produced since the late 1970s to the present.

Key Capabilities

It All Adds Up

Our industry-leading innovations enable a 2x lifetime improvement, a 99% decrease in wafer chipping, a 50% decrease in metals contamination, an 80% decrease in fence “wear-grooving” particle generation, and a 30% average cost-of-ownership savings.

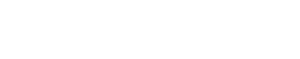

Ultra-low Temperature Elastomers

Coherent ultra-low-temperature elastomer increases wafer cooling performance, boots productivity, and improves pad-to-pad wafer temperature uniformity.

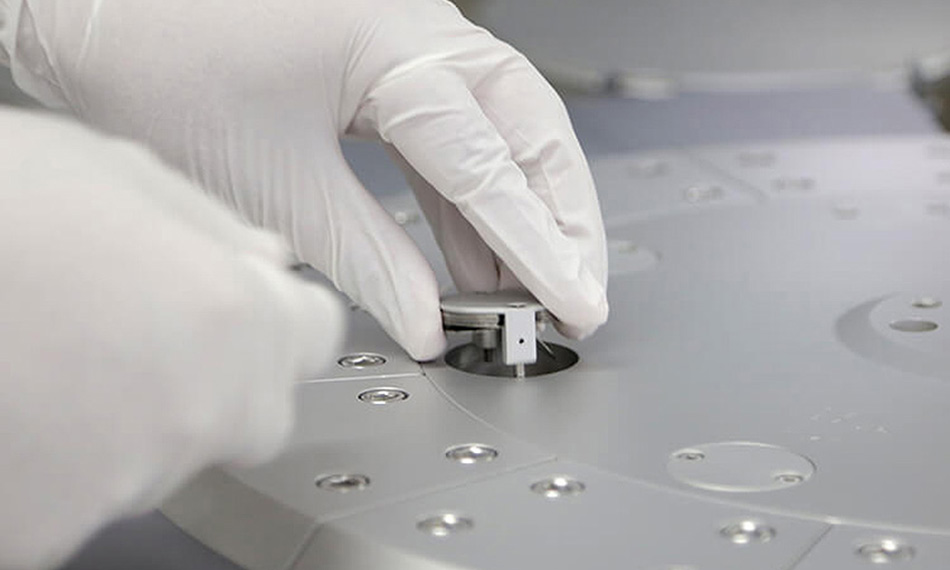

Torlon Fence Assemblies

Utilize high wear resistance Torlon to dramatically improve fence and disk lifetime, substantially decrease wafer chipping, reduce fence wear-grooving, and lower metals contamination.